(475) 405-3613

Bridgeport, CT

BML Tool & MFG .Corp

Your Trusted Partner for High-Quality CNC Components

Precision CNC Machining & Design Solutions You Can Count On

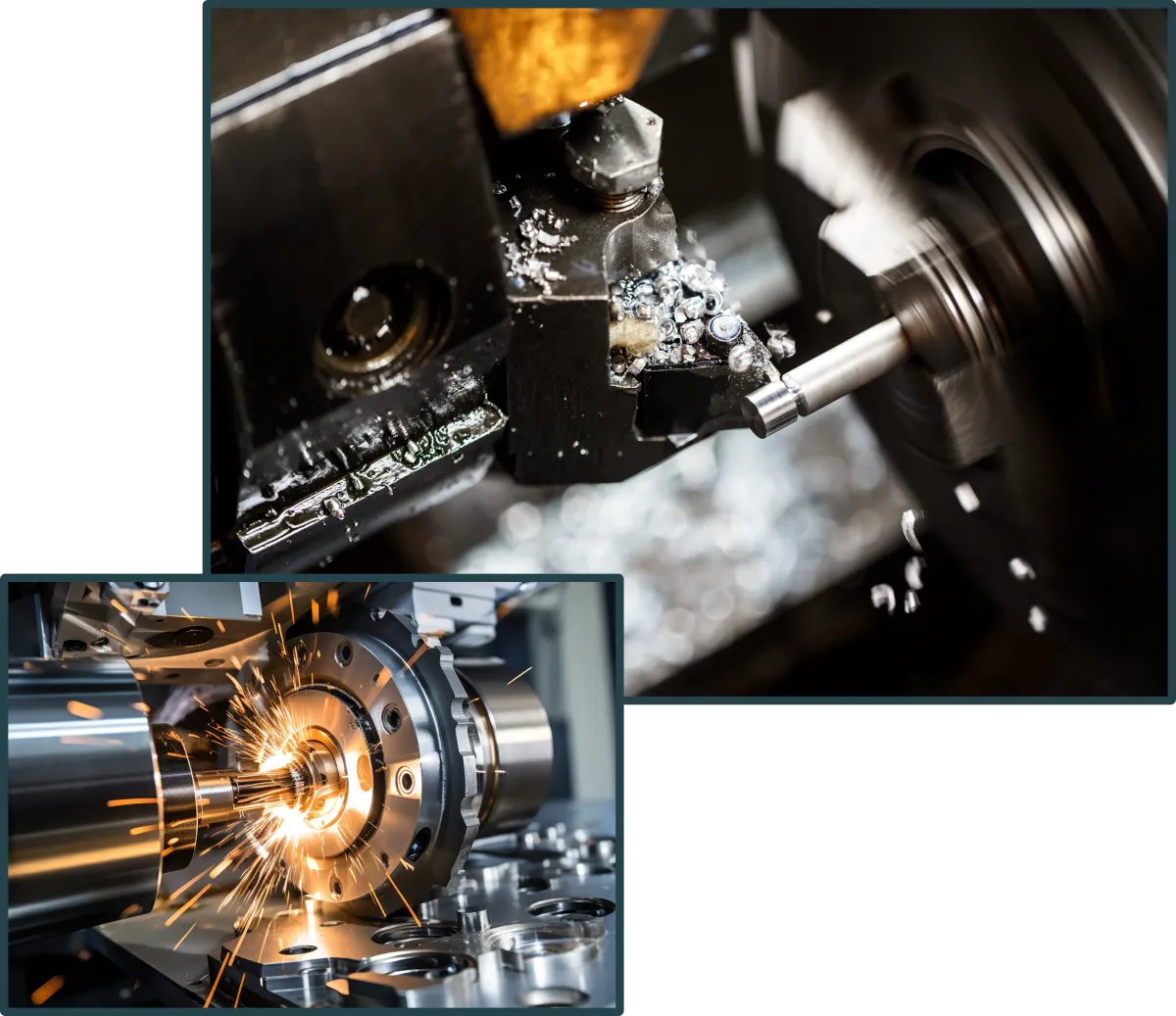

High-precision manufacturing services including milling, turning, CNC machining, and advanced design solutions.

About BML Tool & MFG. Corp

B.M.L. Tool & Manufacturing is an ISO 9001:2015 certified, third-generation, family-owned contract manufacturer based near Bridgeport, Connecticut. Since 1968, we’ve specialized in precision metal components and assemblies for clients across the medical, defense, electrical, and industrial sectors. With over 50 years of tool and die, engineering, and manufacturing expertise, we deliver consistent quality, long-term partnerships, and reliable U.S.-based production from prototype to full-scale runs.

Rapid Turnaround Times – We prioritize speed without compromising quality.

Engineering-First Approach – Every project is backed by design expertise and manufacturability insight.

Flexible, Customer-Focused Service – Low minimums, custom solutions, and responsive support tailored to your needs.

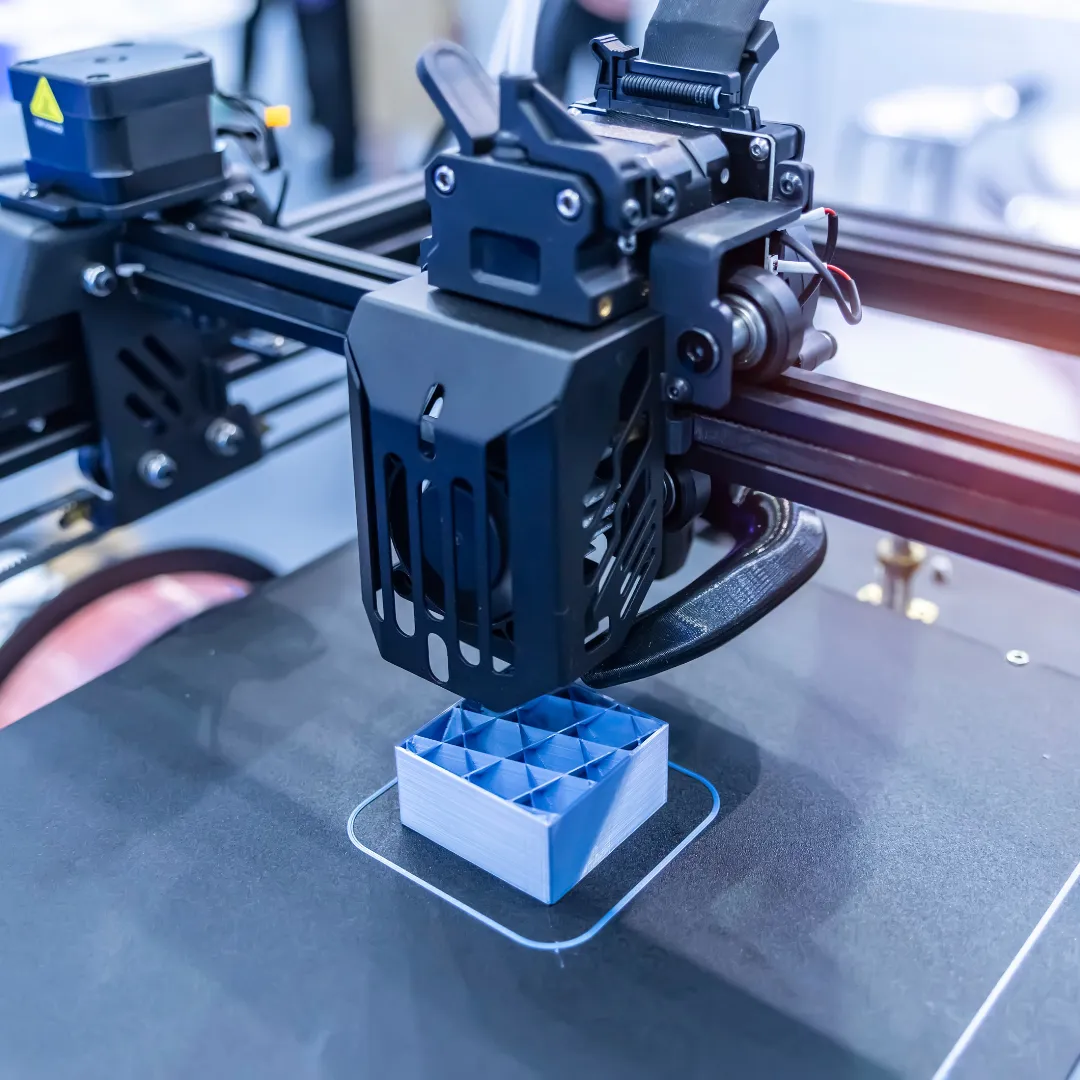

About AZ 3D Print

AZ 3D print is a leading provider of high-precision CNC machining solutions, dedicated to delivering exceptional quality and reliability. With years of industry experience, we specialize in manufacturing precision-engineered components that meet the highest standards of accuracy and performance. Our expertise spans multiple industries, including aerospace, automotive, medical, and industrial manufacturing.

Why Choose BML Tool & MFG .Corp

Unmatched Precision & Quality

We utilize advanced CNC machining technology and rigorous quality control processes to deliver components with exceptional accuracy, durability, and reliability. Every part we produce meets the highest industry standards.

Production & Custom Solutions

Whether you need a single prototype, a small batch, or large-scale manufacturing, we offer flexible machining solutions tailored to your exact requirements. Our state-of-the-art facility is equipped to handle projects of any size.

On-Time Delivery

We understand the importance of deadlines and ensure efficient production workflows to deliver your orders on time, every time. Our customer-focused approach guarantees responsive support and a seamless experience from start to finish.

Advanced Technology & Innovation

We stay ahead of industry advancements by investing in cutting-edge CNC machinery and modern manufacturing techniques, ensuring top-tier precision and efficiency in every project.

Comprehensive Machining & Finishing Services

We understand the importance of deadlines and ensure efficient production workflows to deliver your orders on time, every time. Our customer-focused approach guarantees responsive support and a seamless experience from start to finish.

Experienced & Skilled

Team

From initial prototyping to final finishing, we offer a complete range of services, including milling, turning, fabrication, and surface treatments, providing a one-stop solution for all your machining needs.

What We Provide

At BML Tool & MFG .Corp we specialize in delivering high-precision CNC machining solutions tailored to meet your unique requirements. With advanced technology, skilled craftsmanship, and a commitment to excellence, we provide top-quality components across various industries. Whether you need prototyping, custom machining, or large-scale production, our services are designed to ensure accuracy, durability, and efficiency.

CNC Milling & Turning

Our CNC milling and turning services provide high-precision machining for industries requiring tight tolerances, smooth finishes, and reliable performance. Using advanced multi-axis CNC machines and high-speed lathes, we create complex geometries and precision-turned components with exceptional accuracy. From custom prototypes to full-scale production, we deliver cost-effective, high-quality solutions tailored to your exact specifications.

CNC Milling & Multi-Axis Machining

Our CNC milling services provide unparalleled precision in the production of complex components. Using multi-axis CNC machines, we can create intricate geometries and fine details with exceptional accuracy. This process is ideal for manufacturing parts that require tight tolerances, superior surface finishes, and high-performance capabilities. Whether it’s aerospace components, medical devices, or automotive parts, our milling expertise ensures that every piece is crafted to perfection. By utilizing the latest software and advanced machinery, we deliver custom solutions that meet the specific requirements of each client, ensuring efficiency and cost-effectiveness.

Wire EDM

Our Wire EDM services deliver exceptional accuracy for intricate and tight-tolerance components, especially in hardened or exotic metals. Using electrically charged wire to cut with extreme precision, this process is ideal for tooling, aerospace components, firearms parts, and other applications requiring complex shapes with minimal material stress. Whether for prototyping or production, we ensure sharp detail, clean finishes, and repeatable results

Stamping & Design

B.M.L. Tool & Manufacturing offers precision metal stamping and expert design support to take your parts from concept to production with speed and accuracy. Using progressive dies, deep draw methods, and in-house tooling, we deliver high-quality stamped components with tight tolerances and consistent repeatability. Our experienced engineering team works closely with clients to optimize part designs for performance, manufacturability, and cost-efficiency—ensuring faster lead times and dependable results at every stage.

High-Volume Production & Contract Manufacturing

When it comes to large-scale manufacturing, Mercury Machine Works excels in delivering high-volume production solutions with consistency and efficiency. Our contract manufacturing services provide businesses with a reliable, cost-effective solution for bulk production without compromising on quality. We implement strict quality control measures throughout the entire manufacturing process, ensuring that every component meets the highest industry standards. Our streamlined production capabilities allow us to handle large orders with precision and speed, making us the trusted partner for companies that require dependable machining solutions on a continuous basis.

Frequently Asked Question

What industries do you serve?

We serve a wide range of industries, including manufacturing, aerospace, energy, construction, automotive, and heavy equipment. Whether you need precision machining, welding, or custom fabrication, we can handle it.

What is your turnaround time?

Turnaround time depends on the complexity of the project. We offer expedited services for urgent jobs and maintain efficient workflows to ensure on-time delivery. Contact us for a quote with estimated lead times.

What are your machining capabilities?

We specialize in CNC milling, turning, horizontal and vertical milling, and tight-tolerance machining. Our equipment can handle large parts and high-precision components for industrial applications.

Do you handle small and large production runs?

Yes! We accommodate one-off prototypes, low-volume custom work, and large-scale production runs. No project is too big or too small.

What materials can you machine?

We work with steel, aluminum, stainless steel, titanium, and other alloys. If you have specific material requirements, contact us to discuss your needs.

© 2025 BML Tool & MFG. Corp| All Rights Reserved